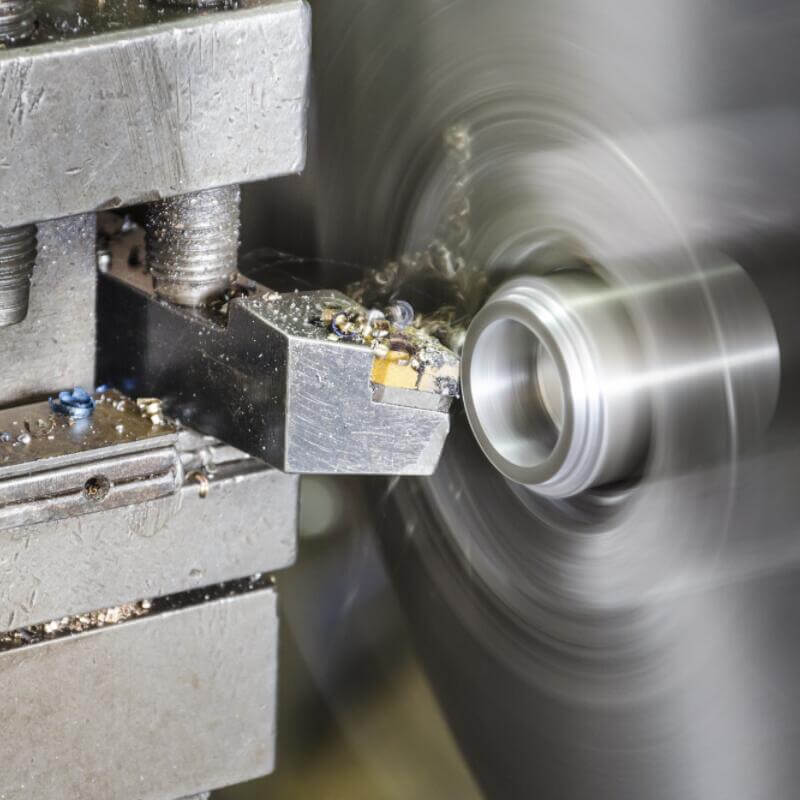

CNC inserts play a crucial role in enhancing the efficiency and productivity of machining processes. To ensure optimal performance and longevity, it is important to take proper measures to increase the service life of CNC inserts. Here are some key tips to achieve this:

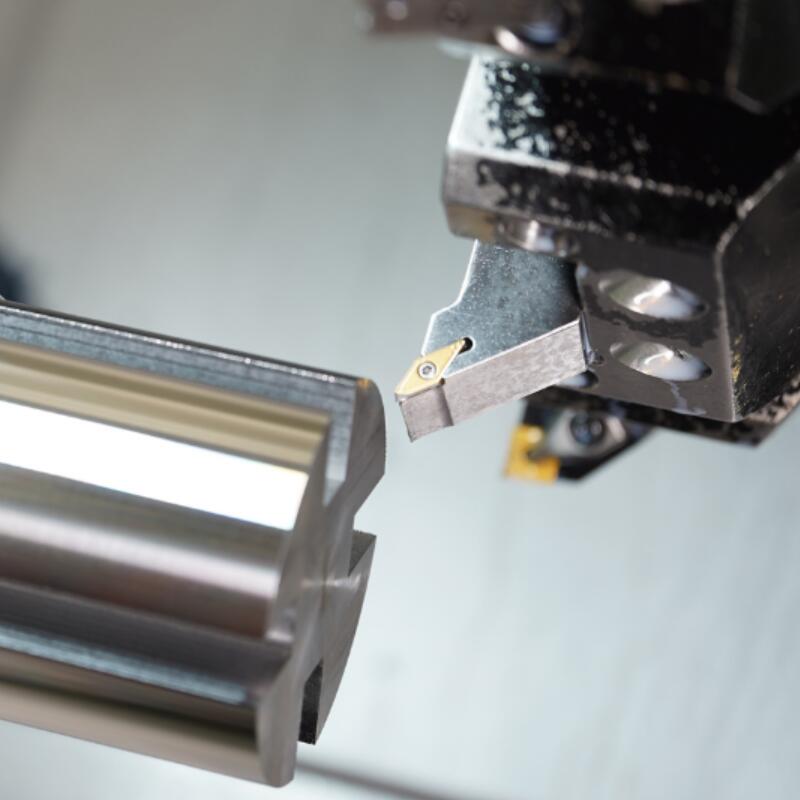

Select the Right Tool: Choosing the appropriate CNC insert for your specific machining application is essential. Consider factors such as material, cutting speed, feed rate, and depth of cut. A mismatched tool can lead to premature wear and reduced tool life.

Handle and Install Tools Correctly: Proper handling and installation of CNC inserts are critical. Avoid dropping or mishandling the inserts, as this can cause damage. Follow the manufacturer's guidelines for installation to ensure a secure and accurate fit.

Use Effective Cooling and Lubrication: Cooling and lubrication are crucial for reducing heat and friction during machining. Utilize coolant and lubricant systems to maintain proper temperature control and prevent premature wear. Ensure that the coolant is compatible with the insert material.

Monitor Cutting Parameters: Regularly monitor and adjust cutting parameters such as cutting speed, feed rate, and depth of cut. Operating at the correct parameters can significantly extend the tool life. Excessive cutting forces or high material removal rates can lead to tool wear and breakage.

Implement Tool Inspection and Maintenance: Regularly inspect CNC inserts for signs of wear, chipping, or damage. Replace worn inserts promptly to avoid compromising the quality of the machining operation. Clean the tool and remove any built-up chips or debris that could affect performance.

Invest in High-Quality Tools: Consider investing in high-quality CNC inserts from reputable manufacturers. While they may have a higher upfront cost, they often provide better performance and longer service life, ultimately reducing overall production costs.

Continuous Training and Skill Development: Stay updated with the latest machining techniques and technologies. Continuous training allows operators to optimize tool usage, improve efficiency, and enhance the service life of CNC inserts.

By following these guidelines, you can effectively increase the service life of CNC inserts and optimize machining operations. Taking the time to choose the right tool, handle and install inserts correctly, use proper cooling and lubrication, monitor cutting parameters, inspect and maintain tools, and invest in high-quality inserts, will result in improved efficiency, reduced downtime, and cost savings.

Contact person: Steve Lee

E-mail: [email protected]

Phone: 86-731-22200908

Address: Floor 4,Building NO.15,Zhichuang Plaza,NO.1299,Liyu Road,Tianyuan District,Zhuzhou City, Hunan, P.R. CHINA

Tel:0086-19973342799

E-mail: [email protected]

WeChat Official Account