Description:

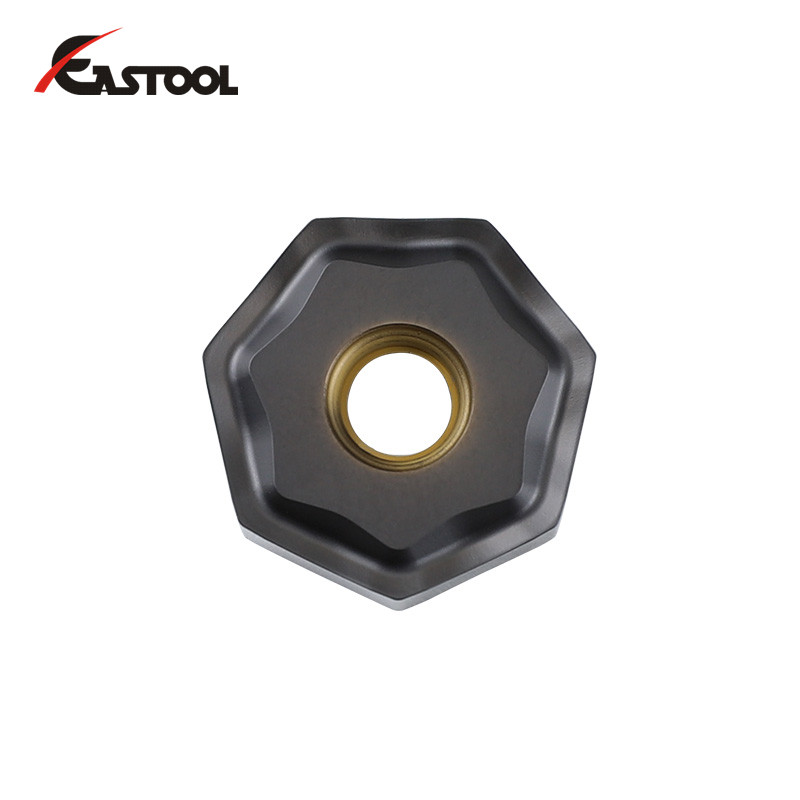

Item NO.:AXMT123504PEER

Coating: Coating

Application: CNC Machine

Structure: Milling Tool

Material: Cemented Carbide

Feature: High Feed Milling

Place of Origin: Hunan Province China

Customized support: OEM

Product Description

Grades Description

| CVD coated cemented carbide | ||

| Grade | Description | Equivalent to ISO |

| YC1015 | MT-CVD coated, the substrate with excellent wear resistance in combination with MT-TiCN,fine grained AL2O3TiN multi-layer coating, which is suitable for finishing of steel. | P05-P15 |

| YC1025 | MT-CVD coated, Cutting edge with good toughness in combination with TiCN+Al2O3(thick)+TiN multi-layer coating,which is suitable for semi-finishing of steel. | P10~P25 |

| YC1035 | MT-CVD coated, the substrate with excellent toughness and plastic deformation resistance in combination with TiCN+Al2O3(thick)+TiN multi-layer coating, which is suitable for roughness of steel. | P20-P35 |

| YC1125 | Special strength toughness of the insert substrates,perfect combinations with MT-TiCN,ultra fine AL2O3,coatings ,common grade for steel,suitable for steel,cast iron,stainess steel in semi-finishing,finishing | P10~P25 |

| YC1315 | The combination of high wear-resistant substrate with MT-TiCN,fine grained Al2O3 and TiN coatings,is a ideal grade of finishing processing of steel,stainess steel in the case of hight speed cutting. | P10~P25 |

| YC1325 | With optimized toughness and hardness of the substrate and MT-TiN, fine grain Al2O3 and TiN coating and with a special post-treatment process, the formation of excellent performance of the double-color coating, suitable for steel, stainless steel and cast iron in semi-finishing and finishing | P10~P25 |

| YC1335 | Substrate with high strength and strong resistance to plastic deformation combined with MT-TiCN,fine grained Al2O3 and TiN coating having great toughness,is suitable for light load ronghing of steel,stainess steel and cast iron | P10~P25 |

| YC2105 | MT-CVD coated, the super fine grain size substrate with excellent hardness in combination with Al2O3(extra thick) coating, the smooth surface, which is suitable for turning and milling of grey cast iron at high speed | K05-K15 |

| YC2115 | MT-CVD coated, the substrate with excellent hardness and stripping resistance in combination with Al2O3(thick) coating, the smooth surface of the tools, which is suitable for turning and milling of cast iron at middle and high speed. | K10-K30 |

| YC2215 | High wear-resistant substrate, new generation coating process with perfect combination of MTTI (CN), Super Al2O3, TiCN coating, initial grades of ductile cast iron, forged cast iron, high cutting speed allowance | K10~K30 |

| PVD coated cemented carbide | ||

| Grade | Description | Equivalent to ISO |

| YP3025 | 2-4um TiALN PVDcoated,combinating with ultra fine particles'substrates with high-toughness, suitabe for all materials,stainless steel, steel, cast alloy in finishing,semi-finishing | P10-P25 K15-K30 |

| YP3125 | 2-4um ALCr+ALCrSiN PVDcoated,combinating with ultra fine particles'substrates with high-toughness, suitabe for all materials,stainless steel, steel , cast alloy in finishing,semi-finishing | P10-P25 K15-K30 M10-M25 |

| YP3225 | 2-4um AlCr + AlCrSiN PVD coating, combined with ultra-fine particle matrix, has high wear resistance, suitable for finishing and semi-finishing of heat-treated steel ,stainless steel and quenched steel | P10-P25 K15-K30 M10-M25 |

| YP3330 | The latest AlCr + AlCrSin PVD coatings, combined with ultra-fine particle substrates, has high wear resistance and excellent performance in finishing and semi-finishing of stainless and hardened steel | P10-P25 K15-K30 M10-M25 |

| YR3025 | Unique material matrix, with 2-4um TiAlN PVD coating, with high toughness and heat resistance, suitable for high temperature alloy, heat resistant alloy and other difficult to process materials finishing, semi-finishing | S10-S25 |

| YR3325 | The latest AlCr + AlCrSin PVD coatings, combined with unique rare metal substrates, offer high wear resistance and excellent performance in finishing and semi-finishing of superalloys and heat resistant alloys | S10-S25 |

Our Advantages

1. High impact resistance, excellent adhesion, reduced friction.

2. Superior wear protection, temperature and oxidation stability.

3. Provides perfect turning surface of the work piece .

4. Less tool breakage, Long tool life.

5. A reliable and secure performance every time.

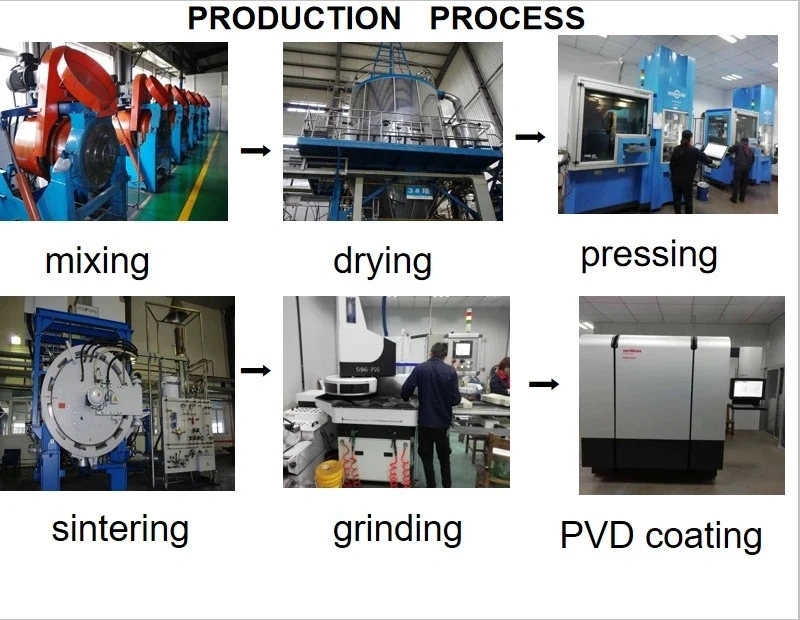

Production Process

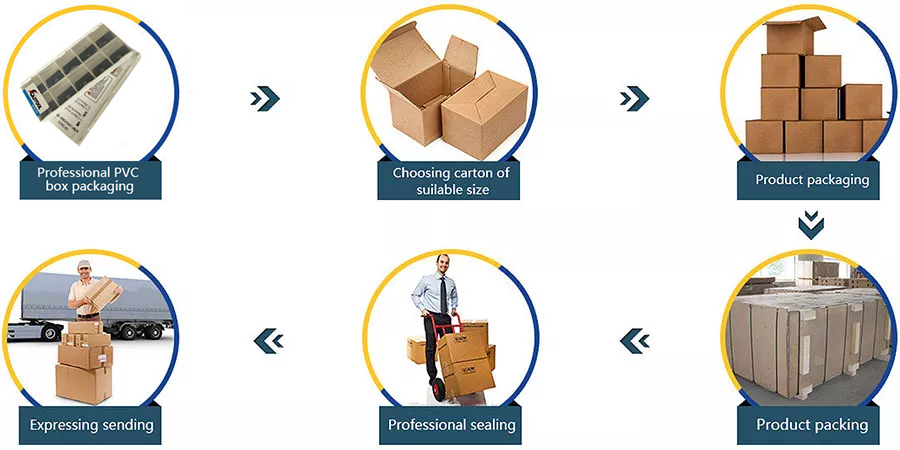

Packing & Delivery

Our Services

| ✔ Pre-sales Service: 24hours online by WhatsApp/ Wechat |

| ✔ Sales Service: Professional sales quotation and precision price for you |

| ✔ After-sales Service: 1-3 days by the delivery time as usual |

| ✔ Technical Support: 20 years engineer in the CNC area |

FAQ

| Q1: Are you a trading company or manufacturer |

| A1: We are a manufacturer of carbide inserts. Our factory located in Zhuzhou City, Hunan Province. Welcome to visit our factory! |

| Q2: What is your minimum order requirement? |

| A2: OEM and customization are available. we accept the small trial order, big order will get a big discount. and try our best to service our customers. |

| Q3: What is the delivery time for production? |

| A3: We usually prepare rich stock for delivery upon payment, 30-35 days for items without stock. |

| Q4: Can you make Non-Standard items? |

| A4: We are specialized in inserts R&D, welcome specical items . |

| Q5: What about the package? |

| A5: We use plastic boxes to pack our products, and filled plastic is shockproof and transported in cartons. also It can make as you need and depend on the shapes of the product. |

Related Searches : SEHT Inserts , Corodrill 818 , R424.9 Inserts , ODMT Inserts , TNMG Inserts

Contact person: Steve Lee

E-mail: [email protected]

Phone: 86-731-22200908

Address: Floor 4,Building NO.15,Zhichuang Plaza,NO.1299,Liyu Road,Tianyuan District,Zhuzhou City, Hunan, P.R. CHINA

Tel:0086-19973342799

E-mail: [email protected]

WeChat Official Account