Description:

Item NO.:CNMM190616/CNMM190624/CNMM250924/CNMM250932

Coating: Coating

Application: CNC Lathe

Structure: Indexable Turning Tool

Material: Cemented carbide

Feature: High Performance Cutting

Place of Origin: Hunan, China

Customized support: OEM

Description

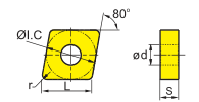

Dimension

|

|||||

| ISO | L | I.C | S | d | r |

| CNMM190616-HY | 19.30 | 19.05 | 6.35 | 7.94 | 1.20 |

| CNMM190624-HY | 19.30 | 19.05 | 6.35 | 7.94 | 1.60 |

| CNMM250924-HY | 25.79 | 25.40 | 9.525 | 9.12 | 2.40 |

| CNMM250932-HY | 25.79 | 25.40 | 9.525 | 9.12 | 3.20 |

Our Advantages

1.Cutting edge inclination designation is good to control chip flow direction and obtains excellent surface quality

2.sharp cutting edge, small cutting force

3.good machining surface quality

4.special chipbreaker design to keep cutting edge sharp and safe

5.good anti impact resistance

6.excellent tool life time

7.High quality gravity turning inserts with competitive price

CVD Coated Cemented Carbide

| Grade | Description | Equivalentto ISO |

| YC1015 | MT-CVD coated, the substrate with exce lent wear resistance in com bination with MT-TiCN, fine grained AL2O3TiN multi-layer coating, which is suitable for finishing of steel. | PO5~P15 |

| YC1025 | MT-CVD coated, Cutting edge with good toughness in combination with TiCN+Al2O3(thick)+TiN multi-layer coating, which is suitable for sem i-finishing of steel. | P10~P25 |

| YC1035 | MT-CVD coated, the substrate with exce lent toughness and plastic deformation resistance in combination with TiCN+Al2O3(thick)+TiN multi-layer coating, which is suitable for roughness of steel. | P20~P35 |

| YC3025 | MT-CVD coated, the substrate with exce lent wear resistance in com bination with TiCN+AI2O3(thick)+TiN multi-layer coating, which is optimal for fin ishing and semi-finishing of stainless steel. | M05~M15 |

| YC3035 | MT-CVD coated, the substrate with special micro structure in com bination with TiCN+Al2O3(thick)+TiN multilayer coating, which is optimal for fin ishing an d roughing of stainless steeI. | M10~M25 |

| YC3045 | MT-CVD coated, the substrate with exce lent toughness in com bination with TiCN+AI2O3(thin)+TIN multi-layer coating, wh ich is optimal for sem i-finishing and roughing of stainless steel. | M20~M35 |

| YC2005 | MT-CVD coated, the super fine grain size substrate with excellent hardness in combination withAl2O3(extra thick) + TiCN(thick) coating, the smooth surface, which is suitable for turning and milling of grey cast iron at high speed | K05~K15 |

| YC2015 | MT-CVD coated, the substrate with exce lent hardness and stripping resistance in combination withAl203(thick) + TiCN(thick) coating, the smooth surface of the tools, which is su itable for turning and milling of cast iron at middle and high speed. | K10~K30 |

| YC2025 | MT-VD coated, the substrate with exce lent wear resistance and toughness in com bination withAl2O3(extra thick) + TiCN(thick) coating, which is suitable for the milling of cast iron(for example, nodular iron) at middle and high speed and interrupted turning. | K20~K35 |

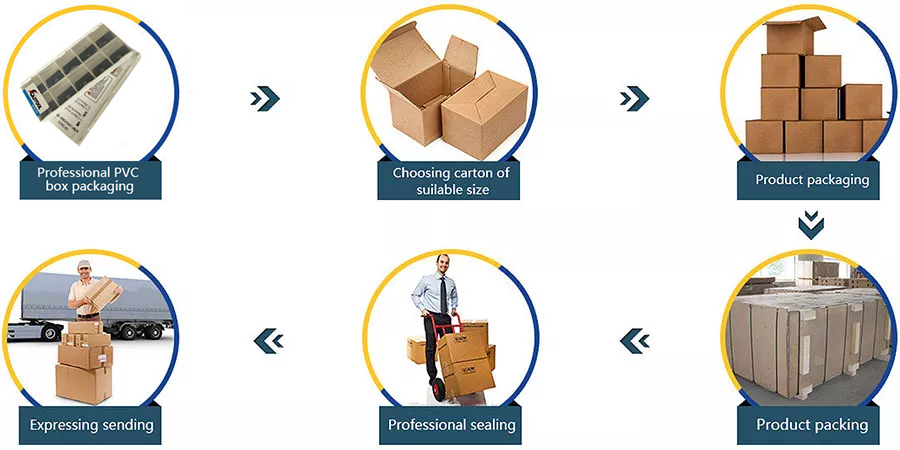

Packing & Delivery

Our Services

| ✔ Pre-sales Service: 24hours online by WhatsApp/ Wechat |

| ✔ Sales Service: Professional sales quotation and precision price for you |

| ✔ After-sales Service: 1-3 days by the delivery time as usual |

| ✔ Technical Support: 20 years engineer in the CNC area |

FAQ

| Q1: Are you a trading company or manufacturer |

| A1: We are a manufacturer of carbide inserts. Our factory located in Zhuzhou City, Hunan Province. Welcome to visit our factory! |

| Q2: What is your minimum order requirement? |

| A2: OEM and customization are available. we accept the small trial order, big order will get a big discount. and try our best to service our customers. |

| Q3: What is the delivery time for production? |

| A3: We usually prepare rich stock for delivery upon payment, 30-35 days for items without stock. |

| Q4: Can you make Non-Standard items? |

| A4: We are specialized in inserts R&D, welcome specical items . |

| Q5: What about the package? |

| A5: We use plastic boxes to pack our products, and filled plastic is shockproof and transported in cartons. also It can make as you need and depend on the shapes of the product. |

Related Searches : R424.9 Inserts , TNMG Inserts , DNMG Inserts , VBMT Inserts , TNMG Inserts

Contact person: Steve Lee

E-mail: [email protected]

Phone: 86-731-22200908

Address: Floor 4,Building NO.15,Zhichuang Plaza,NO.1299,Liyu Road,Tianyuan District,Zhuzhou City, Hunan, P.R. CHINA

Tel:0086-19973342799

E-mail: [email protected]

WeChat Official Account