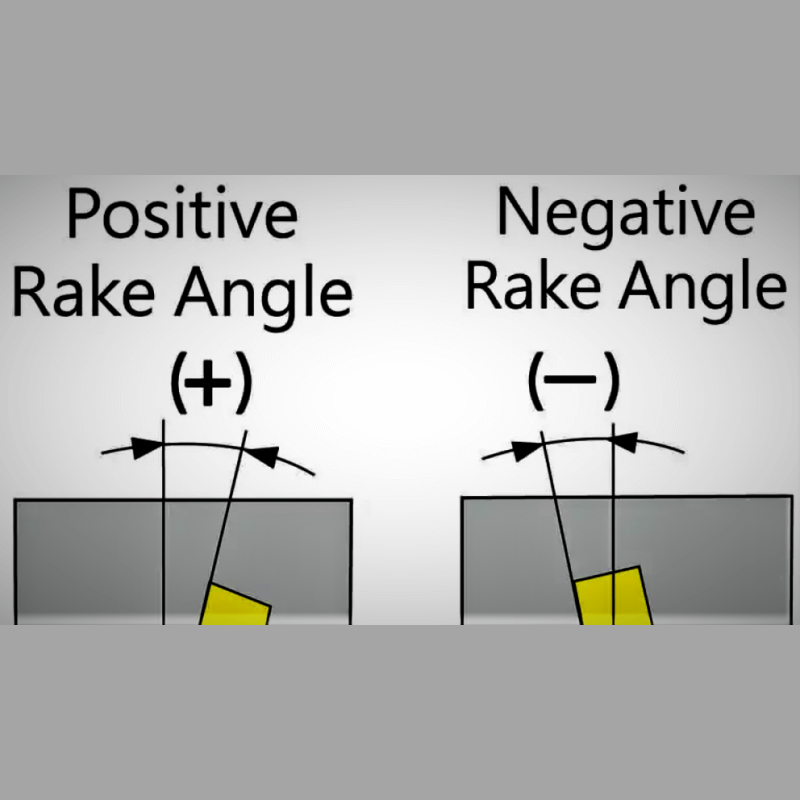

Both positive and negative angle inserts relate to the angle of the cutting edge in relation to the machined surface. Positive angle inserts have a positive angle, and negative angle inserts have a negative angle. The rake angle of the cutting tool is defined as the angle of orientation of the tool’s rake surface from the reference plane (R), and it is measured on some other plane. It is possible for it to be referred to by a variety of names, some of which depend on the plane on which it is projected and measured. At the same time, the rake angle might have a positive value, a negative value, or perhaps no value at all depending on the angle at which the rake surface is inclined with respect to the reference plane. Each of these three varieties comes with its own unique set of benefits and drawbacks. This value has the potential to affect the cutting force and power consumption during machining, as well as the life of the cutting tool, chip deviation, shear angle, tool life, and other factors. The rake angle has an indirect impact on machinability as well.

The clearance angle is where the primary difference between inserts with a positive angle and inserts with a negative angle may be found.

To begin, inserts with negative angles often have clearance angles of zero degrees. On the other hand, the positive angle inserts will always have a clearance angle that falls somewhere between 0 and 90 degrees.

It should come as no surprise that the first letter in the codes for the inserts indicates the form of the insert, whilst the second letter in the code specifies the clearance angle. On the description chart is an insert with the number CCMT120206. The second letter “C” in this letter sequence indicates that the clearance angle is 7 degrees. In this instance, the angle is more than 0 degrees, which is why we refer to it as a positive angle insert. In the same vein, an insert with the coding VNMG160804 reveals that the second letter is a “N.” You can tell that it is a negative angle insert since the explanation chart has the letter “N” next to the clearance angle of 0 degrees. The bottom line is that the presence of the letter “N” in an insert code indicates unequivocally that the insert is made of carbide.

On the other hand, any carbide inserts that do not include the letter “N” in the second position are considered to be positive angle inserts. Single-sided cutting, minimal cutting forces, and side clearance are only some of the characteristics that are offered by the positive angle inserts. In addition to this, it is an excellent option for turning relatively thin components internally as well as turning them outside. Negative angle inserts, on the other hand, can be single or double-sided, have zero-clearance, are designed for heavy cutting circumstances, and have great edge strength.

Positive Angle Inserts and Their Applications

Some cutters retain the positive angle inserts in such a manner that it provides a positive rake angle both axially and radially. This allows for highly free cutting as well as clean and silent machining. This configuration not only provides very low cutting force but also achieves a great surface finish, work hardening on the surface is reduced to a minimum, and excellent surface finish. Machining non-ferrous materials, such as aluminum, copper, and non-metallic materials, and even steels on smaller machines with low power ratings is possible using geometries like these. Because they are more delicate (which can result in cutting edge chippage) and have the potential to pull the workpiece off the table, these positive angle inserts require a special amount of care during the setting up process.

Inserts with a positive angle of attack are typically utilized for cutting through softer materials. Less force is needed to cut through it. However, the cutting edge becomes less effective as the positive value of the rake angle increases. The cutting edge of the tool has a greater propensity to be severed when there is force exerted on the tool. Using inserts with a positive angle makes the tool sharper and more pointed, but they also lower the cutting edge’s strength. It contributes to the avoidance of the creation of build-up edge chip in ductile materials and aids in the production of continued chip in ductile materials.

HSS tools almost always have a positive rake angle applied to them.

They are utilized in the machining of non-ferrous and ferrous metals of low strength.

Positive angle inserts are not recommended for use while high-speed operation is being performed.

Overall Advantages

Clean and precise edging

Effective removal of chips

Good surface smoothness

Overall Disadvantages

The strength of the cutting edge

Unfavorable entry contact

Moves the item of work away from the surface of the machine table

Negative Angle Inserts and Their Applications

Negative angle inserts have an orientation that sends the cutting forces farther back from the edge of the insert by using a combination of negative axial and negative radial rake angles. This allows the cutting forces to be directed further away from the edge of the insert. The rake angle is the result of combining these angles together.

Because of this quality, double Negative angle cutter inserts are able to display stronger insert strength when compared to positive/negative cutters and double Positive angle cutter inserts. Positive angle cutter inserts also have this feature. Due to the geometry of double negative angle inserts, there is a possibility of poor chip flow, which might lead to worries about clogging. The geometry of these inserts is like this despite the fact that they are quite robust and durable.

It is essential to have a machine that has the necessary power, in addition to a rigid setup, in order to ensure that the cutting tool and the workpiece are securely attached. Cast iron is an excellent material for using negative angle insert geometries; however, in order to make advantage of these geometries, a stiff setup is required. Also, keep in mind that recent developments in technology have made it possible to include chip breakers inside inserts. This is something that was previously impossible. Because of this, modern negative angle inserts may be machined with a larger degree of flexibility than was previously feasible. This was not the case in the past. Because of this, negative angle inserts are capable of processing a wide variety of materials effectively provided that the appropriate chip groove profile is used.

Inserts with a negative angle are used to cut through materials with a high strength rating since they are stronger. When inserts with a negative angle are utilized, the cutting edges may gain enhanced strength, which is beneficial.

Adhesion may be prevented by using inserts with a negative angle as the angle of the insert.

Work on enhancing the surface quality; it may be used in high-speed cutting operations; increase the cutting force during machining; this will also increase the amount of power used by the process.

In most cases, a negative rake angle is applied to cemented carbide tools.

Raise the temperature at the cutting edge by raising the amount of vibration and friction.

Overall Advantages

Increases cutting edge strength

Increases productivity

Brings the workpiece closer to the machine table

Negative inserts allow for twice as many cutting edges to be employed in a single operation

Overall Disadvantages

High cutting pressures

Chip accumulation

Obstruction of the workpiece

Contact person: Steve Lee

E-mail: [email protected]

Phone: 86-731-22200908

Address: Floor 4,Building NO.15,Zhichuang Plaza,NO.1299,Liyu Road,Tianyuan District,Zhuzhou City, Hunan, P.R. CHINA

Tel:0086-19973342799

E-mail: [email protected]

WeChat Official Account