In recent years, the global tungsten market has experienced continuous price increases due to tightening raw material supply, rising energy costs, and growing demand from high-end manufacturing industries. As tungsten powder is the core raw material of cemented carbide products, these fluctuations inevitably impact the cost structure of carbide cutting tools.

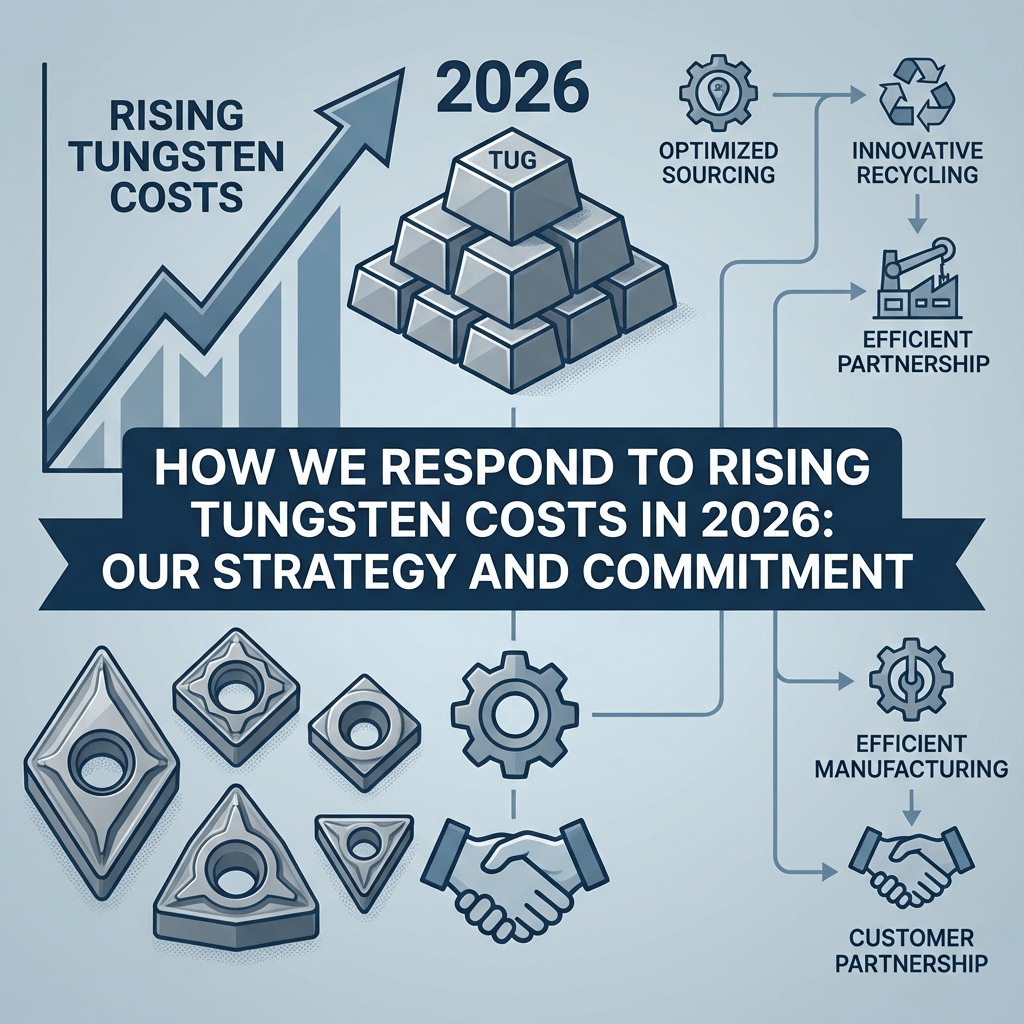

In 2026, tungsten prices are expected to remain at a relatively high level. As a professional manufacturer of carbide inserts and cutting tools, we believe transparency, stability, and long-term value are more important than short-term reactions. This article explains how we respond to rising tungsten costs — and how we continue to protect our customers’ interests.

The increase in tungsten raw material prices is driven by several structural factors:

Limited global tungsten resources, with mining highly concentrated in a few regions

Stricter environmental regulations, increasing production costs

Rising demand from aerospace, automotive, and energy industries

Higher energy and transportation costs worldwide

These factors are long-term in nature, meaning price volatility is likely to continue rather than disappear.

When facing rising material costs, our priority is not simply passing the pressure on to customers. Instead, we focus on long-term cooperation, product reliability, and cost efficiency.

Our guiding principles:

Maintain stable product quality

Ensure consistent supply

Optimize cost-performance ratio

Provide transparent communication

We continuously improve powder formulation and sintering processes to reduce material waste while maintaining hardness, toughness, and wear resistance.

Through upgraded equipment and refined manufacturing processes, we reduce unit production costs and improve yield consistency.

We establish long-term partnerships with stable tungsten powder suppliers to minimize short-term price fluctuations and ensure steady supply.

From powder inspection to final product testing, every step is strictly controlled to prevent quality deviations caused by raw material changes.

Even under rising cost pressure, our customers can continue to expect:

✔ Stable product performance

✔ Consistent dimensional accuracy

✔ Reliable delivery schedules

✔ Competitive long-term pricing

✔ Technical support and application guidance

Rather than focusing only on unit price, we help customers reduce total machining cost, including:

Longer tool life

Reduced tool change frequency

Improved machining efficiency

Lower scrap rates

Looking ahead to 2026, our commitment remains clear:

Quality first, always

Transparent pricing strategy

Continuous product optimization

Long-term cooperation with customers

Investment in R&D and process improvement

We believe that real value lies not in short-term cost reductions, but in reliable performance, stable supply, and trust built over time.

Rising tungsten prices are a challenge shared by the entire industry. However, with responsible sourcing, efficient manufacturing, and a customer-first mindset, we are confident in our ability to deliver high-quality carbide tools without compromise.

If you would like to learn more about our products, pricing strategy, or technical solutions for your application, please feel free to contact our team. We are always ready to support your machining success.

Contact person: Steve Lee

E-mail: [email protected]

Phone: 86-731-22200908

Address: Floor 4,Building NO.15,Zhichuang Plaza,NO.1299,Liyu Road,Tianyuan District,Zhuzhou City, Hunan, P.R. CHINA

Tel:0086-19973342799

E-mail: [email protected]

WeChat Official Account